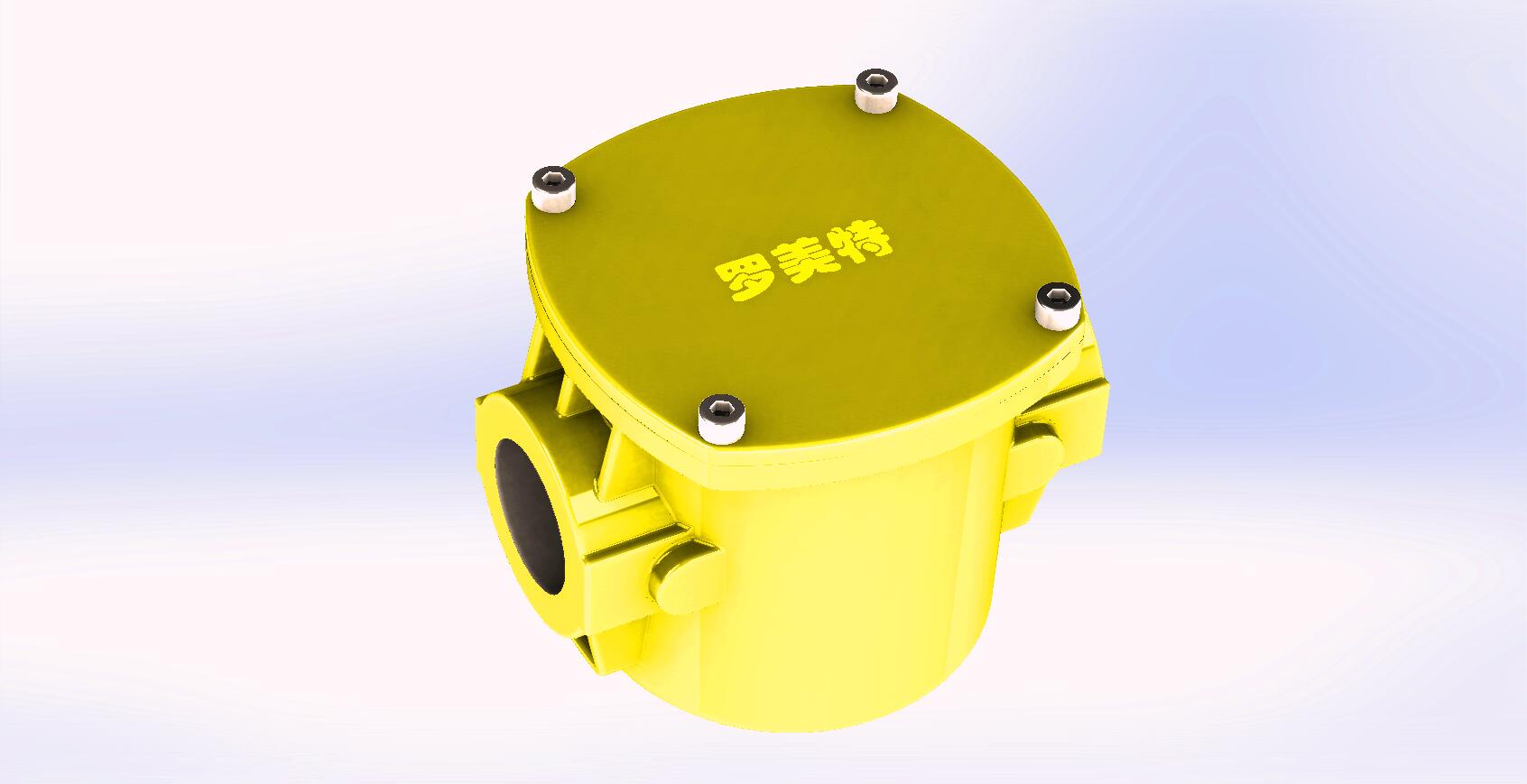

GQ (C)/GQ series gas filters are the matching products of gas turbine flowmeter and gas waist wheel flowmeter produced by our company. When the gas quality is poor, it is used to filter the dust, droplets and impurities contained in the air flow in the pipeline to ensure the normal operation of the flowmeter. The filter is also suitable for various pressure regulating devices.

- The filter core has large filtration area, low pressure loss, corrosion resistance and no two pollution.

The filter element can be cleaned many times and used repeatedly.

Compact structure, easy installation and simple maintenance.

The differential pressure gauge (GQC Series) can display the dirty degree of filter element.

DN250 and DN300 are designed and manufactured according to GB150-1998 "steel pressure vessel".

It is suitable for natural gas, artificial gas, liquefied petroleum gas, air and other media.

Modle &Specification

GQ-40

GQ-50

GQ-80

GQ-100

GQ-150

GQ-200

GQ-250

GQ-300

Max flow (m³/h)

100

160

400

650

1600

2500

4000

6500

Max Pressure Loass(K pa)

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

Filtration Accuracv

50um (180目/英寸2)

Nominal Pressure

1.6; 2.5;4.0

Material of filter screen

Stainless steel screen

Material of housing

1020 #

Q235B、16MnR

Working Temp (℃)

(-30℃~+80℃)

型号

口径

(DN)总长

(L)总高

(H)简体

法兰

(φA)简体

直径

(φB)管道法兰安装尺寸

执行标准GB/T9119-2000D

D1

d

N

PN1.6~4.0

GQ(C)-25

25

240

340

180

108

115

85

14

4

GQ-25L

263

260

164

116

GQ-40L

40

240

200

150

120

150

110

18

4

GQ(C)-50

50

300

435

200

133

165

125

18

4

GQ-50L

240

200

150

120

GQ(C)-80

380

535

250

168

200

160

18

8

GQ(C)-100

100

440

655

310

219

PN1.6

220

180

18

8

PN2.5~4.0

235

190

22

8

GQ(C)-150

150

570

900

410

325

PN1.6

285

240

22

8

PN2.5~4.0

300

250

26

8

GQ(C)-200

200

670

1136

540

426

PN1.6

340

295

22

12

PN2.5

360

310

26

12

PN4.0

375

320

30

12

GQ(C)-250

250

866

1580

680

550

PN1.6

405

355

26

12

PN2.5

425

370

30

12

PN4.0

450

385

33

12

GQ(C)-300

300

956

1800

730

616

PN1.6

460

410

26

12

1000

1800

760

620

PN2.5

485

430

30

16

PN4.0

515

450

33

16

- 1: determines the discharge period according to the conditions of use so as to eliminate the accumulated water and impurities in time.

2: When the filter screen is blocked by dirt and the pressure loss increases obviously, it should be cleaned in time, and if there is damage, it should be replaced in time.

3: Use kerosene or other detergent, clean the dirt carefully with non-metallic brush, and know that the filter element is clean as before.

4: When cleaning or replacing the filter core, the inlet and outlet of the filter should be cut off first, and the gas in the filter should be replaced with nitrogen. The gas should be discharged into the safe area. After each cleaning, the leak should be re-detected. After confirming that there is no leak, the air in the filter should be replaced with nitrogen, and then the operation can continue.

5:GQ(C) series should close the inlet and outlet valves at both ends of the differential pressure gauge before ventilation, and then slowly open the two inlet and outlet valves at the same time when the pressure is stable to avoid excessive pressure on one side of the differential pressure gauge.

- Index >

- Product Center >

- Gas converter >

Product Center