G series roots flowmeter (Y type) guarantees the machanical quality campared with imported products, and applies a large number of imported components. Electronic componets incorport domesctic application habits and integrate temperature and pressure correction, romote transmission, recharge, valve control into one assembly. The product is mainly used in gas metering for industrial and commercial users. It has an exclusive invention patent; the product is exquisite and beautiful in appearance, whose performance is leading position in the industry, with a variety of specification.

The product’s mechanical performance is stable.

Range ratio can reach 1:300. Initial flow rate is 0.04m³/h.

Intergrated Mechanica counting, Temperature and Pressure correction, Remote transmission, Recharge, Valve control into one assembly.

Integrated circuit and low efficiency design. The battary life can last more than 3 years, and the memery can store data for 12 months ( a set of data per hour).

Specification

Flow Range

Flange OD

Pressure Loss

Flange Distance

Length

m3/h

mm

kPa

mm

mm

G10

0.32-16

DN40

0.1

171

205

G16

0.5-25

DN40

0.1

171

205

G25

0.5-40

DN40

0.1

171

224

G40

0.65-65

DN50

0.15

171

348

G65

0.67-100

DN50

0.24

171

398

G100

0.8-160

DN80

0.26

171

497

G160

1.25-250

DN100

0.32

241

500

G250

2-400

DN100

0.53

241

688

G400

3.25-650

DN100

0.75

241

699

G400

3.5-700

DN150

0.76

406

580

G650

8-1600

DN150

0.71

406

717

G1000

8-1600

DN200

0.78

406

786

Remarks: 1. DN40, 50, 80 domestic assembly, working pressure 1.2Mpa

2. DN100 and above are imported from overseas, working pressure 1.2Mpa

3. Accurancy grade: 1.0Path DN (mm)DN(mm)

Model specification

A

A1

H1

B

Threaded connection

Flange connection

H

G

H

D

K

n

d

DN25

G10

195

60

104

100

182

1”

171

115

80

4

14

G16

227

76

104

100

182

1”

171

115

80

4

14

G25

261

93

104

100

182

1”

171

140

100

4

18

DN32

G10

195

60

104

100

182

1¼”

171

140

100

4

18

G16

227

76

104

100

182

1¼”

171

140

100

4

18

G25

261

93

104

100

182

1¼”

171

140

100

4

18

DN40

G10

195

60

104

100

182

1¼”

171

140

100

4

18

G16

227

76

104

100

182

1¼”

171

140

100

4

18

G25

261

93

104

100

182

1¼”

171

140

100

4

18

Note: pipeline through DN, thread connection size and flange joint size can also be provided according to user requirements.

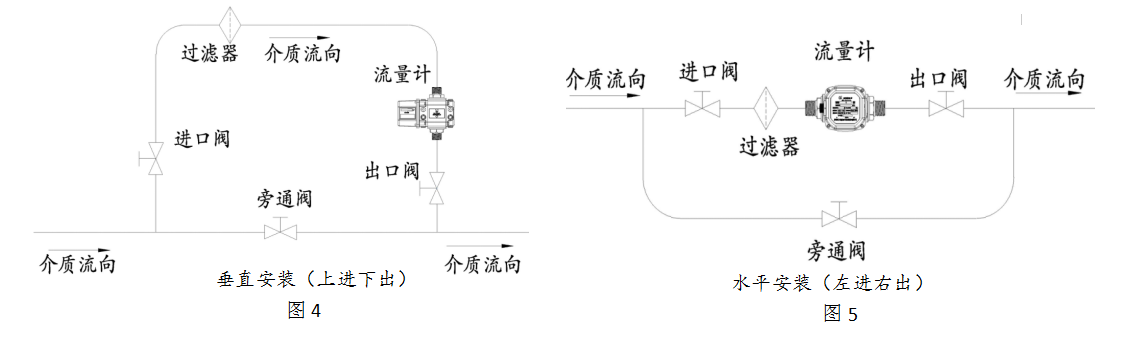

There are two ways to install flowmeters: vertical installation and horizontal installation (Fig. 4, Fig. 5). Vertical installation is recommended. When the flowmeter is installed vertically, the inlet end of the medium should be above and the air flow should flow from top to bottom, so that the rotor has self-cleaning ability to the dirt. When installed horizontally, the axis of the inlet and outlet end of the flowmeter should not be lower than the axis of the pipeline, so as to avoid the dirty impurities in the medium remaining in the flowmeter's flow detection chamber. Normal speed. When installing, the filter must be arranged upstream of the flowmeter to improve the cleanliness of the medium. (the filter is supplied by our company).

Matters needing attention

1. After the flowmeter has been installed correctly, before entering the normal operation, the corresponding type of lubricating oil should be added to the flowmeter according to the requirements. During the operation, the quality and quantity of oil should be checked regularly, and the lubricating oil should be replaced and supplemented in time to ensure the normal operation of the flowmeter, and the fixed part of the flowmeter should not be loosened at will.

In order to ensure the normal use of flowmeters, attention should be paid to and prevention of overpressure and overflow of flowmeters during operation.

3 field installation and maintenance must turn off external power before opening. And there should be no harmful gas on the site.

Maintenance and battery replacement must be carried out in a safe place. Maintenance can only be carried out when the presence of non-combustible gases is confirmed at the installation site.

When using external power supply, it must be matched with the related equipment (safety grille) identified by the explosion-proof certification authority to form the intrinsic safety explosion-proof system before it can be used in the corresponding explosive dangerous places. The shielded cable is used to connect the cable, and the shielding layer is grounded in a safe place. The distribution parameters of the cable are controlled within 0.05 uF/1mH.

6 users are not allowed to change electrical components in their own products at will. When installing, using and maintaining products, users must abide by the relevant provisions of GB50058-92 "Code for Design of Electric Power Devices in Explosive and Fire Hazardous Environment" and "Code for Electrical Safety in Explosive Hazardous Places of the People's Republic of China".

- Index >

- Product Center >

- G Series Roots flowmeter (Type Y) >

Product Center